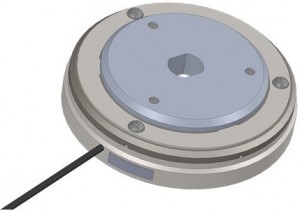

Electromagnetic brake type EH 160

CONSTRUCTION AND APPLICATION:

The EH160 electro-brake is designed for braking a rotating shaft. Its operation is based on an electromagnet that pulls two metal discs together, between which there is an asbestos-free friction lining. It is intended for dry work only. When installing and using the electro-brake at the final location, pay attention not to soil the friction surfaces with oil, grease or other friction reducing substance, as this will significantly reduce the braking moment.

Steel surfaces are protected against corrosion by galvanizing. The device is equipped with a return spring that ensures the brake disengages when the power is turned off. The gap at the abrasive disc should be between 0.2 - 0.5mm wide when the brake is not energized.

The electro-brake coil is a significant inductive load for the power supply system - a sudden interruption of the current flow through the coil will cause reverse voltage at its terminals. In order to protect the coil against electric breakdown, the power supply system should have adequate protection to suppress backward voltage pulses (e.g. semiconductor diode).

It is also possible to make electromagnets for individual orders with the parameters set by the customer.

Detailed technical data on the attached catalog card.